-

Posts

230 -

Joined

-

Last visited

-

Days Won

8

Content Type

Profiles

Forums

Events

Gallery

Posts posted by Abyssdncr

-

-

I used this for all of mine:

http://www.kudzucraft.net/Rope-and-Thread/Stitching-Twine.html

...but it's out of stock...

I can't think of any good reason braided line wouldn't work for sewing, but I would want to make sure it's something that will melt with heat after you tie off and snip the tag ends to discourage the knots from slipping loose over time.

-

Screws go left and right of center just enough to get screws in at the front and back. There will be enough clamping force.

-

21 hours ago, Walter T said:

I haven't purchased my fabric yet. It was recommended that I use an 8 ounce polyester because of the ease of application. Now I don't know if that means it is an economy fabric or not, this is my first boat. What determines economy fabric.

http://www.kudzucraft.net/Uncoated-fabrics/

Skip the "economy" fabric and save yourself lots of headaches - the cost savings really isn't worth it in the long run.

-

I'd approach this task much the same as approaching the bow or stern tips - cut your cords off just shy of the hatch lip and stitch the fabric up tight at the termination and staple under as Jeff described. I went the other route on my hatch with the double corded stitch though and offset the hatch to the side and stitched the seam around the hatch lip. If it makes you feel any better - you're probably overthinking this - once you go to make it happen, the solution will present itself by necessity.

-

1

1

-

-

Walter,

What fabric are you using? My answer would change depending on what you use, not from a durability standpoint, because I think it's a toss-up, but from an "effectiveness of sealing" perspective. If you're using the economy fabric, I believe you'll get a much better seal in fewer coats with less hastle using spar varnish from the local BBS. If you're going with the premium fabric, I'd go the paint route. I did two painted boats with the economy and one of them still has pinholes somewhere and the other took spray on fill primer to get a bunch of spots. With the varnished one, three coats on the bottom, two on the top - good to go and doesn't leak a drop. The main thing with the varnish is to apply it as sparingly as possible at first so you don't get runs and drips that go through, because every application error will be visible from both directions...

Hope this helps!

-

If it were me, I'd push them into place and lash. If there's any distortion to the frame, it'll add a smidge of rocker which shouldn't hurt the design at all in my opinion.

-

1

1

-

-

5 hours ago, Kudzu said:

Never heard of Kydex, how does it handle UV? I recommend plastic cutting boards at one time but they are not UV resistant and only lasted 2 seasons. They were falling apart literally by the second. That is why I switched over to brass.

Honestly, no idea, but considering it's more popular applications in the sporting goods and automotive applications, I don't think it's an issue. I'm using 0.080" sheets. Lots of wear resistance...for the price. I can replace them half a dozen times at half the cost of brass.

-

I've recently started experimenting with kydex for rub strips when Keel Easy failed me at the tips. Rough cut size, thermoform carefully with a heat gun, sand it to final shape / debur the edges, and rubber cement in place. If it gets too worn, peel it off and wash, rinse, repeat.

-

Finally got her out on the river yesterday. Fairly tight and winding section - definitely made it a workout managing the length around some of the bends, but it fulfilled my desired outcome of decent cargo with a shallow waterline for low water conditions. Should have used ply instead of cedar on the seat mounting blocks, because I broke both sides removing the seat without being gentle enough. Should be easy enough of a repair though.

This one's officially in the "done" column. ?

-

-

My CLC has a two layer foam seat that takes a tractor seat shape in use. Between that and a Surf to Summit high back band, it's one of the most comfortable boats for me. If it's just got the one layer of foam though, it wouldn't be nearly as effective.

Post back with your Redfish install. I'd love to see it.

-

I've put 36.5 river miles in my tandem so far this year. Only one of the kiddos has confidence in moving water, so it's nice for them to have me in the back as a safety net for them. Also put a number of hours in it fishing the local lake. We've actually had lots of fun learning to coordinate maneuvers.

Me and the wife are good to go; me and a kid are good to go; any other combo of the household...not so much. We had a full house tandem night last week. Me and the wife in a Dirigo tandem, the older girls in the Wood Duck with the dog, and the little kids in the Wallops Island. Holy crap, watching the older ones try to go fast in a straight line was funny, but watching the little two was absolutely hilarious!

My buddy put it like this: tandem boats are like tandem bikes - whatever direction your relationship is going, a tandem will get you there faster.

I really like that Dirigo tandem though...

-

-

On 5/16/2017 at 7:36 AM, benhardt57 said:

I'm almost happy with the way it turned out, but I think something a little stiffer would have resulted in the crisper look I was hoping for.

I really like the curvy look of the coaming pulled down tight like that. I was just looking at that picture thinking, "I'm gonna do that on the next one..." and then I read your last post.

I think if you just adapt to using the gunwales as your support for getting in / out instead of the coaming, it might grow on you too.

-

Are the Long Shot plans not adapted for the laminated beam yet or was this just an older set of plans?

Great lookin' yak, CJ!

-

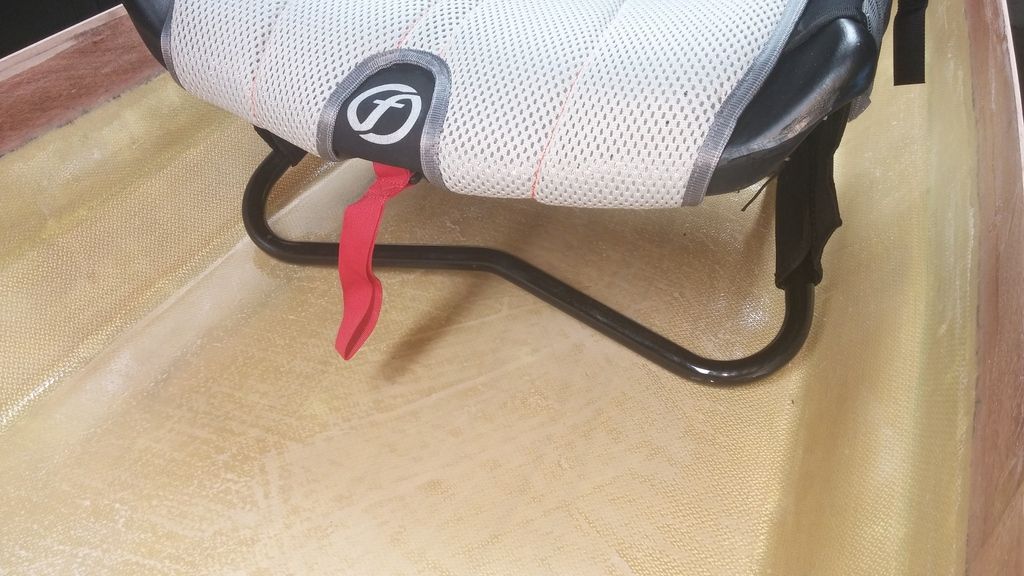

Ever slowly moving forward. Lots of sanding, even though it doesn't show it. Foot braces positioned, but still need glassed on. Solo seat mount is in, still noodling on a second position, but the second mount is mostly fabbed, just need to notch the second set of aluminum straps. Should I glass over the cedar pieces that are notched for the rear bar or will epoxy and paint be sufficient? I'm just worried about losing the seat if I flip in strong river current and the seat gets wedged on a log something while the boat is getting pushed along.

Will add pads as pictured for the front legs to rest/slide on...plus central mounts for a nylon strap to hold the front end down. Probably won't get much else done this week, but I have a 4 day weekend coming up that should end with a full rudder and seat install and more little spots filled with epoxy.

-

I can only guess at weight now by comparison to others with published weights and say 70 lbs. plus or minus without the seat.

Test paddle success. Definitely doesn't track like the Wood Duck, but not nearly as "wandering" as short kayaks. So, as expected in the handling department. Solo seat position ended up being way farther forward than I would have guessed...according to the pictures, at least. With the seat more toward the middle, it definitely tracked better.

Seat height checks. Started to "feel" like a canoe at the 5th click, but still totally manageable at the highest setting. Standing was shaky, but I didn't get wet.

Long story short, gonna be great for it's intended purpose, but the downwind sail and rudder can wait for a bit, budgetarily speaking.

-

8 hours in the basement today, and if the winds cooperate, I'll be out for a test paddle tomorrow evening to settle on a seat location. All plywood endgrain is capped and sealed, everything has at least one coat of epoxy, if not 8...

The other big question is no doubt handling. I love the way my Wood Duck Double responds on the water, be it fishing in the lake with a kiddo or cruising down the river loaded to camp. If this is similar, I'll be thrilled. In addition to tracking, I want to try out various seat heights to see how she'll perform if I'm just anchored & fishing with respect to stability. I'm hoping this seat will let me spend at least a few hours without my butt going numb, even if it's just due to altering height.

Supposing all things check out accordingly, next up will be seat support structure, a rudder kit, and provisions for the downwind sail. Fairing, paint, and varnish too, if I can settle on a paint scheme.

-

-

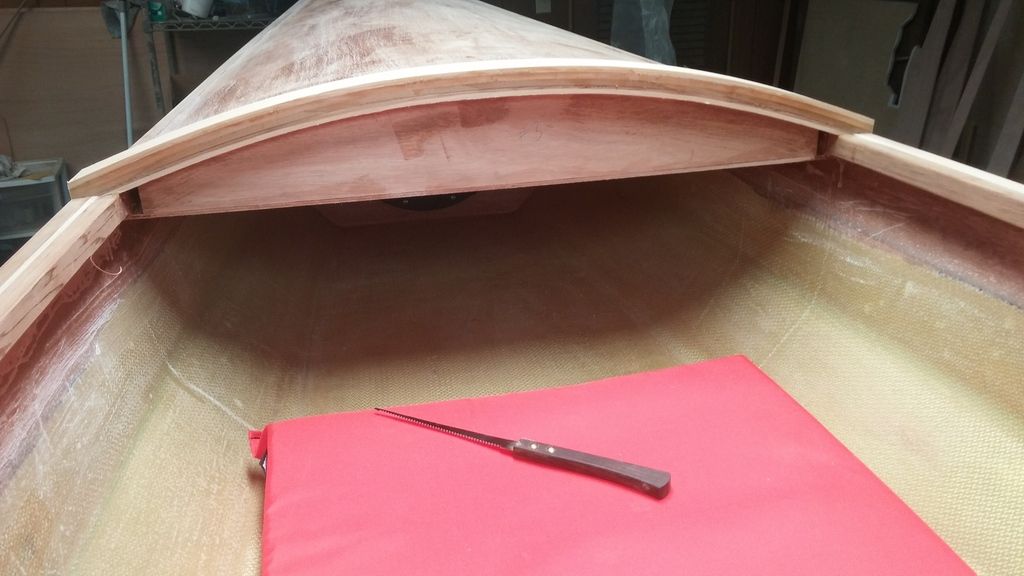

Outwales on and drying. I mounted them flush with the decks which made them sit about an eighth of an inch proud all through the cockpit area. Then, I planed down some white cedar and dropped it into the gap covering up the plywood end grain. When it's dry, I'll plane and sand all three pieces together into what should look like a nice continuous gunwale. I couldn't...wouldn't...spend the time to make the segmented gunwale the way I wanted, so this will have to do. Plan to taper the ends into the false stems over the last foot or so. The aft false stem was cut with a vertical section at the top to accommodate a rudder gudgeon.

Even though I really did try to wipe up all the excess epoxy when attaching the inwales, there's a nasty run the full length of the cockpit that needs to be scraped off. Then, on to the coaming lips for the decks (do canoes have "coamings"?). Eventually, I'd like to fab a skirt, so I'm putting lips on the decks' edges, regardless of what they're called.

Also, the decks are easy to buckle in the wider areas, so when I flip it over to fillet the decks from the inside, I'm going to add some stiffeners in the center along the inner roofs of the decks. Gonna have to get creative with the upper mast support since it won't be at a bulkhead station, but we'll cross that bridge when we get there.

Still waffling about a paint scheme. The seat has orange stitching, but I haven't settled on a good way to tie it altogether so it's not so flagrantly disjointed - "Why the hell did you just bolt a commercial kayak seat into a handbuilt canoe?" Maybe there isn't a good tie, but I'm doing it anyway.

Regardless, I have less than two weeks to get all the boat stuff out of the basement...

-

-

-

-

Heavy on bottom, light on top?

in Kudzu Craft Forum

Posted

I did something similar for one of the kid's yaks for aesthetic purposes - it can work. However, I believe the weight "saved" with the lighter fabric gets totally negated with the added weight of the rub strips, staples, screws, and silicone required for a leak proof installation. I'd just sew the 9 oz up the top with the running whip stitch for the lightest weight if I were you & felt the need for the more robust fabric.